From New Dawn 54 (May-June 1999

No one in the world really knows how the Great Pyramid of Giza was built – that is, of course, except for myself! Such is how I start a lecture or speech on this controversial subject. As an attention grabber, it works well, but it is nothing compared to the subject matter at hand.

There are about as many proposed methods of construction as there are people who propose theories on the subject, with the informed reader aware of most. The following brief and condensed explanation of the Great Pyramid’s construction is one of the most fantastic and unconventional methods ever proposed. With some consideration, this is possibly the method that makes the most sense.

The following narrative of the Great Pyramid’s construction is based on a privately published and very rare book called Pharaoh’s Pump written by the late independent researcher, Edward J. Kunkel. This is the book that is so highly regarded in the recent best selling book, 5/5/2000: Ice, the Ultimate Disasterby Richard W. Noone.

Pharaoh’s Water Pump

Traditional Egyptologists explain the subterranean passages and the chamber deep below the Great Pyramid as a change in design. Egyptologists tell us after working so long and hard on this part of construction the Pharaoh decided he wanted to be entombed in a chamber up in the pyramid. Pyramidologists tell us the passages are designed and built as Man’s prophetic chronology set in stone. Others say the descending passage and subterranean room were used to view the stars.

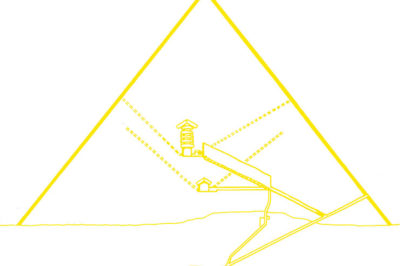

The Pharaoh’s Pump Foundation and the book Pharaoh’s Pump maintain that these passages cut into solid bedrock are a colossal and enormous hydraulic ram pump! This hydraulic ram pump is built on a gigantic scale never duplicated in the ancient or modern world. Massive amounts of pumped water was used to supply a series of water locks, up to the Great Pyramid, transporting barges with stones to the building site. With its own pumped water and a series of water locks as a lifting medium, the Great Pyramid supplied its own water power to build itself!

Before the Great Pyramid’s construction, the site was not flat but a granite outcropping. The shape and size of this outcropping is unknown. In the finished pyramid the granite outcropping protrudes up to a height near the bottom of the Grand Gallery. The site is on a gradual sloping hillside. Uphill from the Great Pyramid is the Libyan Desert.

Almost all agree that the two subterranean shafts and the subterranean room were excavated before the pyramid was built. Herodotus, the famous Greek historian, tells us ten years were spent in preparation. The subterranean excavations at the construction site were the preparatory work needed before construction started.

At this stage of construction, there was only one mechanical element needed to create the largest, most colossal, hydraulic ram water pump ever created! That one single mechanical element being a drain and valve. The dead end shaft, cut in the south-eastern corner of the Subterranean Chamber is 2 feet 7 inches wide, 2 feet 5 inches high and 52 feet 9 inches long. Its direction is from true north to south. Its position is horizontal and it lies at the lowest corner of the lowest chamber. This suggests that it functioned as a drain, but it dead ends in the rock. Even though it is 105 feet below the base of the building, it is still high enough from the outside to function as a drain.

The cutting of this shaft must have been an awful job. It is so small – only 29 inches high and 31 inches wide with a length of 52 feet, leaving very little elbow room. Maybe a midget crew cut it. I’ll never believe that its existence is due to over-sight or gross error. I’ll never shrug it off as a miscalculation. I have too much respect for the ancient engineers for that. Why is there so much interest in the lowest shaft of the Subterranean Chamber? The answer lies in this simple fact: a waste duct in this particular area would be definite proof that the engineers had cut a simple water ram in the solid rock!

Around the base of the Great Pyramid and in its immediate vicinity are a number of unusual and hard to explain cuttings in the solid rock. Among these cuttings are the “crypts” that contain the so-called “sunships.” Traditional Egyptologists maintain these ships were entombed at the same time as the Pharaoh and the ships were used during the funereal precession. The location of the sun ship pit and other features indicate that they were created at the same time as the Great Pyramid and were part of a drain system with a valve that would complete the greatest water ram pump in the world. The dead end shaft that leads south from the Subterranean Chamber heads directly towards the sunship pit. This water drain system of the pump was unnecessary after the Great Pyramid was completed. Later the ancients used the pit for ceremonial purposes after the functional purpose of this cutting was no longer needed. Our current understanding of the passage from the Subterranean Chamber towards the sunship pit is that the passage is a dead end.

Apparently this dead end has never been examined with the idea in mind that it may be a drain duct. In 1954, two sun ships were discovered in the rock hewn cavity at the very southern base of the pyramid. It is reasonable to assume that the size and shape of this cavity has been surveyed and recorded. Such data is hard to come by. It would be interesting to examine the north wall and ascertain the distance from it to the terminus of the dead end. The terminus of the dead end is about 83 feet south of dead centre of the building. This leaves a space of about 300 feet to its southern base. In short, I believe there exists a connecting duct, between the dead end and the sun ship cavity. Explorers might hit pay-dirt if they take a good hard look at the end of the dead end and the north wall of the sun ship’s crypt.

This pump was a simple water ram of monstrous proportions. A ram that pumps far more water than it wastes. My guestimate? At least 4 tons for one ton of wastage to a height of 60 feet during a time cycle of one minute. The sun ship cavity itself may be part of it. My line of reasoning follows this pattern. Originally, the cavity was cut for use as part of the drain for the water pump. When the Great Pyramid was completed the pit was no longer needed. Only after the construction of the Great Pyramid were the sun ships installed in their pits. Why not decorate and touch up these pits with some regal trappings?

I have believed from the very beginning that this tube is part of a drain and that its outlet is sealed in as clever a fashion as the ancients managed to conceal other openings. It is utterly fantastic to believe that the ancient engineers overlooked this common device – a drain that can be opened and closed at will and thus employ the same mechanics of the common ram. I predict that one or more baffle walls will be found in the horizontal tube leading south from the subterranean chamber, the function of which is to slow down the high velocity of water discharge and ease the shock exerted on the waste valve.

What will the drain valve look like? It will be a “door with pivots.” We call them butter-fly valves. They are easy to open and close and are operated by a handle. Pairs of holes with granite seats to fit this type of valve are found in the passage near the top of the lower diagonal. No one, for a moment, doubt that these seats and holes are for this type of “door.”

There are two other check valves in the subterranean cuttings. A short distance down in the solid rock of the lower diagonal is an offset “wherein,” says Sir Flinders Petrie (The Pyramids and Temples of Giza), “hung a door that swung inward.” A pair of eight inch round holes are found here, one in the east wall and the other in the west wall. Adjacent to these round holes is granite masonry. This mechanical element, given a hydraulic interpretation, is a check-valve. The holes support a round shaft and the granite masonry is the valve seat. Halfway up the passage leading from the Subterranean Chamber to the lower part of the Grand Gallery is the Grotto. Detailed research indicates it too in ancient times housed a check valve.

How the Water Was Pumped

The Ancients were doing what every engineer does before he undertakes a massive construction project. The machine comes first, and in this case it was a water pump. These subterranean cuttings formed a hydraulic ram pump. The lower diagonal holds about 88 tons of water! When the valve in the drain is opened the water in the lower diagonal moves down. Then the drain valve is closed. The water in the lower diagonal continues to move down compressing the air in the Subterranean Chamber. This chamber has an air capacity of 7000 cubic feet! Once this moving water has compressed the air to the maximum, the water stops moving. At that point, the check valve in the upper end of the lower diagonal closes. The highly compressed air in the Subterranean Chamber pushes water up through the “grotto” and onto the rocky knoll. Research including computer modelling shows that the water ram pump would easily pump water to a height of the top of the completed Great Pyramid.

Water ram pumps are a very interesting device and are still being built and sold to this day. Water ram pumps work and work well. When you shut a water faucet off and the pipes rattle, think about the ancient engineers who used the same force in a colossal scale to move and lift the blocks in constructing the Great Pyramid.

What existed at this point is a mound of rock with a passage in the centre that leads up from the Subterranean Chamber and the descending passage down to the Subterranean Chamber. All of the subterranean passages and subterranean valves were finished and the colossal hydraulic ram was ready to go. The source of water for the pump was the ancient lake of Moeris. This lake was huge, about the size of Lake Erie. Its elevation was above the base of the Great Pyramid. Water for the pump was brought to the site and channelled into the lower diagonal from this lake.

If the hydraulic ram pump pushes water up the central shaft it will be wasted because the water will just flow down the granite outcropping. At this stage, parabulious walls were built around the building site. This created a catch basin for the water. Near the base of the Great Pyramid to this day can be seen these same “parabolus walls” made of earth, which surround the building. The walls form a rectangular basin and look like the remains of an ancient catch basin or reservoir. The 14 foot vein of river silt found inside is mighty convincing evidence that in ancient times this rectangular enclosure held water, and formed a pond 180 acres in area. And the little rocky knoll, upon which the pyramid stands, became a little rocky island.

The Construction Process

Try to envision, if you will, the rocky knoll high above the Nile before a single block was set. It must have been a bleak, bare, gray mound of limestone. It was not flat. The perimeter had to be levelled off to create a base for the first row of casing stones. To use the water, it must be caught. The simplest device to catch it is a ditch. Once a ditch was cut in the location of the first row of casing stones and filled with water, it formed a perfect device for a levelling operation. Water would pour from the ditch at the lowest contour of the rock. This lowest contour determined the elevation of the base. Five hundred chisellers could be put to work at one time and whack the perimeter of the base down to a uniform level. The still water in the ditch would be their gauge, and simplify surveying operations.

The next step would be to move the casing stones from the quarry across the river up to the base of the prepared building site of the Great Pyramid. How would you bring 16 ton stones from across the river, that are already on barges, up to the site of the Great Pyramid? A site with subterranean cuttings that are a hydraulic ram pump. Evidence indicates that a series of water locks from the Nile to the building site were created to move the stones up from the river to the building site. The locks worked just as the water locks work in the Panama Canal. The subterranean cuttings that are a colossal hydraulic ram pump supplied the needed water to operate the locks.

Comparatively recent excavations have exposed the cutting of a giant rock-hewn stairway with huge risers, ascending from the basin near the Nile River to the top of the knoll. This cutting has the basic characteristics of the remains of a series of water-locks, although every relic that would indicate water-locks is gone. The accepted explanation for this cutting was to extract blocks for structural use in the pyramids. I never believed this explanation because the cutting is too precise, too neat, and too regular. If the ancients were quarrying blocks alone, the sides, the treads, and the risers would have been left rough and uneven.

As they are today, these stairs are too wide to be of practical use as water-locks, but if a wall were built in the centre of the steps, dividing the stairway in two, the result would be two narrower sets of stairs. If appropriate masonry were placed in this divided stairway with pairs of water-gates made of wooden planks, the locks would be complete. When water was pumped into the locks they would have been ready to take stone laden barges up one set of locks, while the empty barges came down through the other. I believe that this stairway of locks is part of the 60 foot roadway described by Herodotus.

The completion of the first course of casing stones formed a rectangular enclosure in which water could be impounded, forming a pool or artificial pond. Once this pool was created, barges with the rough interior stones were brought up the locks into the pool and put in place with remarkable ease. The block was moved into place by workers wading waist high in a pool of water. When the block was in position, the water level was lowered, which set the stone gently down on the floor of the pool. When this pool was filled with the rough interior stones, the next course of casing stones were brought up and placed above the previous course of casing stones. This created a higher pool of water. Barges with rough interior stones were brought up the locks and put in place with remarkable ease, until that pool was filled. A 16 ton casing stone or even a large 40 ton monolithic block could be moved and set as gently as a mother lays her sleeping babe in a crib. This simple process continued, step by step, course by course, level by level, until the Great Pyramid was completed!

The workers moved the stones into the correct position on special barges. Then the water in the pool was lowered, gently lowering the stone in place. The barges were such that when the stone was lowered into place the barge could be removed from the stone, similar to a modern day forklift. With the use of water as a powerful and easily controlled lifting medium, the massive weight and size of the stones created no problems. Using the largest casing stones possible is a measure of economy. Large stones mean less quarrying work and finishing of the faces. The same is true for the rough cut stones one sees now that the casing stones have been removed. Since moving the stones to the building site is the least labour intensive part of the construction, the use of very large stones makes the job easier.

It is interesting to note that the sides of the Great Pyramid “bend inward.” Or to put it another way, the sides of the Great Pyramid have a concave crease from the apex down to the centre of the base of each side. The Great Pyramid of Giza actually has eight sides. This was vital because of the hydrostatic pressure of the water inside the pyramid during construction. The Great Pyramid is the only pyramid in the world with this characteristic. This feature must have made the design and construction more difficult, but it was a must. Each side bends inward against the pressure of the water inside of the pyramid just as a dam like Hoover Dam bends towards the force of the water it holds back. The casing stones have precision joints that are cemented together to make the exterior of the Great Pyramid water tight. This was not to keep the pesky Egyptian rain out, but to hold water in during construction.

According to Herodotus: “… they raised the remaining stones to their places by means of machines formed of short wooden planks. The first machine raised them from the ground to the top of the first step, on this there was another machine, which received the stone on its arrival, and conveyed it to the second step, whence a third machine advanced it still higher.” Another translator of Herodotus offers this translation: “They made it first in the shape of stairs, and lifted up the stones that remained with engines made of short timbers. From the ground they raised them to the first range of stairs; when the stone came up to this, it was set in another engine that stood on the first range, and drawn up from this to the second range; and thence by another engine to the third, for there were as many engines as there were ranges of stairs . . .” In the first, the word “machine” is used, while in the second, the word, “engine.” But the gist of the translations are identical.

In modern usage, the words ‘engine’ and ‘machine’ are often used synonymously. And it may be here that in the translation of the ancient Greek the meaning of these two words are even more closely allied. For example, the dictionary defines the word catapult as “an ancient engine of war.” By a physicist’s definition, a catapult is not an engine of war, but a machine of war. An engine uses fuel directly to make it go. More than a hundred years ago, the US state of Ohio built an elaborate system of canals. Even today, in the vicinity of Akron, Ohio, century old water-locks are in operation. Nowadays, pleasure craft pass through them. The lock-gates are made of wooden planks about eight feet long. These locks are truly machines. They are water elevators and a floating body can be raised or lowered in them. They are made of stone andshort wooden planks. I believe that the machines Herodotus described were a series of water-locks. Elsewhere in the same volume he tells of seeing an old dry-dock that was used by King Necos to repair damaged war vessels. Think of this: How can anyone build a dry-dock and not use a water-lock? It cannot be done.

The construction of the Great Pyramid continues. Upon the completion of each level, the next level above was assembled on the level before it. But how are the massive blocks moved up to ever greater heights as the construction progresses? As each level was completed, a water lock was built to move the blocks up to the next level. These series of locks moved blocks up the north face of the pyramid, one lock per level, all the way to the top. When the top of the pyramid was completed, the top lock was not needed. That lock was removed and the casing stones put in place. Small stones and rubble were placed in the area of the removed lock by hand. If solid close fitting stones were used then the water from the pump could not supply water to the rest of the locks below the top lock. Each lock was removed and replaced with casing stones from the top to the bottom with small stones and rubble placed in the area of the locks. Herodotus says he was told the pyramid was finished from the top, downward. To this day one can see along the north face where small stones and rubble fill the location of the series of locks.

Most have heard the legends and myths that tell the stones were levitated into place by some unknown force. Some fables speak of the stones being somehow floated to their destination. These stories from distant past, lacking detail, do speak great truth. Even though this description is brief and abbreviated, you now know the answer to the riddle of the ages! You know how the Great Pyramid was built! No massive ramps almost the size of the pyramid itself. No sweated brow or tortured back. No multitudes of slaves harnessed like animals heaving to the crack of the whip. No aliens from distant worlds. Just workers wading waist deep in cool pools of water. Men moving barges, operating valves, locks and pumps under the watchful eye of talented Ancient Engineers.

Building the Great Pyramid was not an exercise of oppression by a ruthless Pharaoh. Building the Great Pyramid was a snap! Its construction was an orderly, systematic, inventive and wondrous, piece of cake. But why build it? WHY? What was its purpose? Was it a tomb to be used once by an all powerful ruler? Was it built as a sacred place for those initiated in secret societies of higher wisdom to perform unknown rites? Was it somehow an observatory to view the stars? Was it built as prophecy in stone to confirm Biblical prophecies? What is the meaning of the mysterious interior chambers and passages? Is it a power source that we do not understand? Is it a temple, tomb or machine? The answer to why the Great Pyramid was built is the subject of the second half of this series to be published in the next issue of New Dawn.

© New Dawn Magazine and the respective author.

For our reproduction notice, click here.